The Polestar 5 will be built atop a ‘bespoke’ bonded aluminum platform – TechCrunch

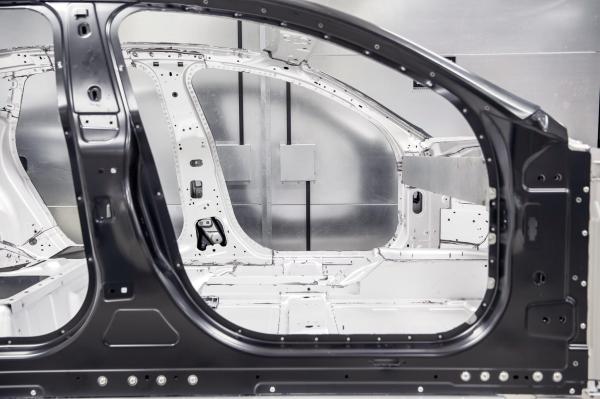

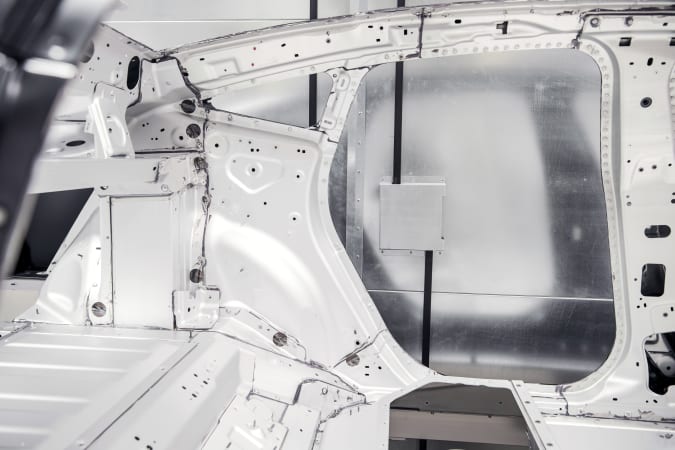

The Polestar 5 will be cut from a different cloth than its predecessors when it launches at the end of 2024. Polestar announced on Tuesday that its upcoming electric performance sedan will ride atop an entirely new, lightweight bonded aluminum platform rather, than the welded design used by the 1 and 2.

Polestar

Because welding aluminum generally halves its yield strength, you end up having to use double the amount of material to achieve the same performance — which defeats the whole purpose of using the lightweight metal in the first place. Bonding aluminum parts together (ie affixing them with screws and adhesive), on the other hand, cuts down on the materials needed but at the cost of extended production times.

“The cycle time to cure the adhesive is comparatively long compared to a typical welding cell,” Steve Swift, director of vehicle engineering at Polestar, told Engadget via email, adding “the strategy to control build consistency is very different to conventional construction methods.”

In order to maintain the material advantages of using aluminum while minimizing the production penalties of bonding the pieces together, Polestar’s engineering team developed a faster manufacturing process that assembles the vehicle body and battery platform as one.

Pingback: hostel bangkok

Pingback: mushroom growing kit colorado